Welcome back to our series on mastering the industrialization process. Having already dived deep into the initial phases, focusing on Planning, we’re now focusing on the next stage that can make or break your product’s market entry – Develop. This stage is pivotal, making sure your brilliant ideas and detailed designs translate into a viable, market-ready product.

Check Systems Are Fully Operational

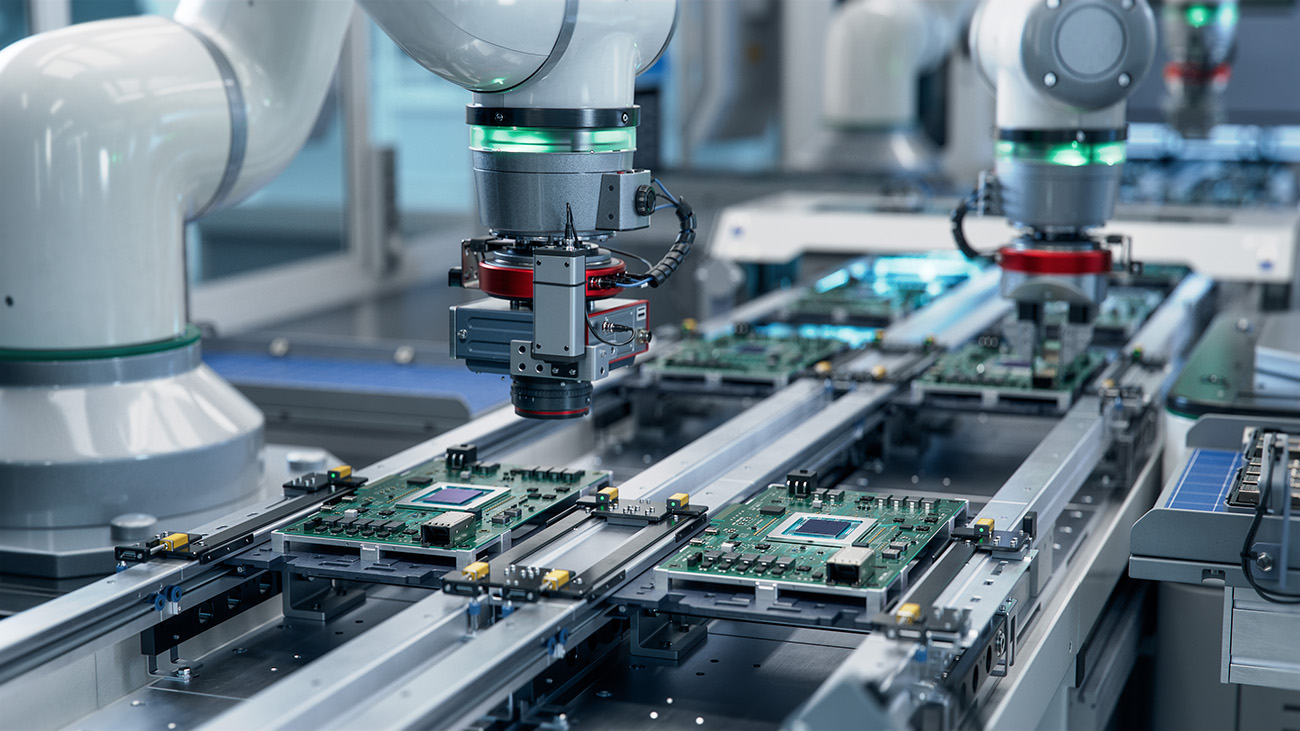

Being successful at the Develop stage – where engineering, design, prototyping, and compliance are hammered out – requires a meticulous approach to both production and testing, as in a perfect world, the two should go hand in hand. This phase is your final opportunity to ensure everything is in perfect alignment before you get production rolling, and to turn back if things aren’t quite right, before it’s too late.

Before your production line springs into action, it’s essential to verify that your supply chain is up to the task of feeding that production, in both quantity and quality components. Delays in receiving materials can not only set back your production schedule, they can also inflate costs and reduce your competitive edge – a triple threat of problems. Once you know everything is going to be on time – or at the very least, you have backup suppliers that can get you out of trouble – make sure everything coming in is up to spec. Substandard parts risk product failures, damaging customer trust and brand reputation – not great when you’re launching a new product.

Production preparation goes beyond just having the tools and materials needed to make a product, you also need to consider the human requirement, not just in terms of time, but in terms of knowledge. This alignment is crucial for a smooth manufacturing process where every team member knows exactly what is expected of them. We could write a whole extra piece on training alone, but we know every company has its own approach – needless to say, it’s very, very important.

Testing, Testing

If we could write an extra piece on training, we could quite literally write a book on testing.

Testing isn’t just a tick-box exercise. So often we speak to customers who think testing is just a basic function of quality control, rather than a genuine value add for their entire production. Key to good testing is robust testing protocols that can accurately assess product functionality and durability under realistic conditions. After that – and this is the thing that so many product owner miss – is managing that test data so that it can be turned into actionable insights as you look to continuously improve.

If you aren’t familiar with WATS, you should check it out right now. It’s the test data management platform built for production and already used by the likes of ABB, Sennheiser, and Siemens.

Just as in managing test data effectively, you also need a very strong document control system in place along with an action tracker so that feedback can be effectively tracked as you begin to improve what you do during development, once the product is released.

Most manufacturers will adhere to quality standards that require fairly meticulous document control, but it’s always worth assessing if the way you are managing it is best suited to how you operate today. That’s because these systems usually develop organically and often bloat as a result.

WATS Test Data Management system, for Electronics Manufacturing.

Crafting Quality With Confidence

All in all, being successful at the Develop phase of industrialization is a lot more complicated than just ‘setting up’ production and testing. Hopefully we’ve gone some way in demonstrating that it’s not just a case of crossing off items on a shopping list of requirements, it’s going to affect so many parts of your business if done right. But, if it is done right, it has the potential to catapult your quality far beyond where you’re at right now. The efforts you invest in perfecting production and testing are reflected in every unit that ships to your customers.

We’ve literally just described the tip of the iceberg in this article because the Develop stage is exceptionally deep. With that said, you’ve got another gem to look forward to in our next piece, as we cover the final steps of industrialization and how to get started mastering them.

If optimizing your production and testing phases seems daunting, Virinco is here to help. With our deep expertise in industrialization, we can guide you through each step, ensuring your product launches successfully and sustainably. Contact us today to see how we can transform your production challenges into triumphs.

This is the fourth article in a five-part series on industrialization. Read the others:

The Definition of Industrialization In 2024

When you think about industrialization, what comes to mind? If you Google it you’ll.. read more

How We See The Industrialization Circle

This time we’re going one level deeper, looking at the individual steps of industrialization… read more.

In Industrialization, Planning Is Everything

Plan and Analyze. If you don’t get these two steps right, your industrialization will fail…. read more.

Developing Production And Testing – One Key To Successful Industrialization

This stage is pivotal, making sure your brilliant ideas and detailed designs translate into a viable, market-ready product… read more

Ready Production And Continuously Improve

The final steps of industrialization – Ready Production and Continuous Improvement – are where the magic happens… read more.