When you think about industrialization, what comes to mind? If you Google it you’ll be inundated with pictures of plumes of smoke billowing from factories. While the transition from human-powered production to machine-powered is a part of the history of industrialization, the state of play in 2024 is quite a bit different, particularly in electronics manufacturing.

With that in mind, we’re rolling out a five-piece series on industrialization that explains what it is, why it’s important to your business, and how to go about doing it right. What makes us an authority on industrialization? Well, we’ve been helping companies like Kongsberg, Eltek, and FMC with industrialization for over twenty years, so you could say it’s our specialist subject.

How Industrialization Has Evolved

Early industrialization began in the 18th century in Great Britain and saw the economic setup of the country shift from a focus on agricultural production to an economy built on mechanized manufacturing. The best modern example of this shift was in the late 80s in China where radical changes in how the country’s economy operated turned it into the manufacturing powerhouse we all know today.

As advancements in technologies and methodologies have continued to improve the ways manufacturers produce goods, new schools of thought have developed around managing those improvements more proactively. That’s essentially what industrialization is in the context of electronics manufacturing.

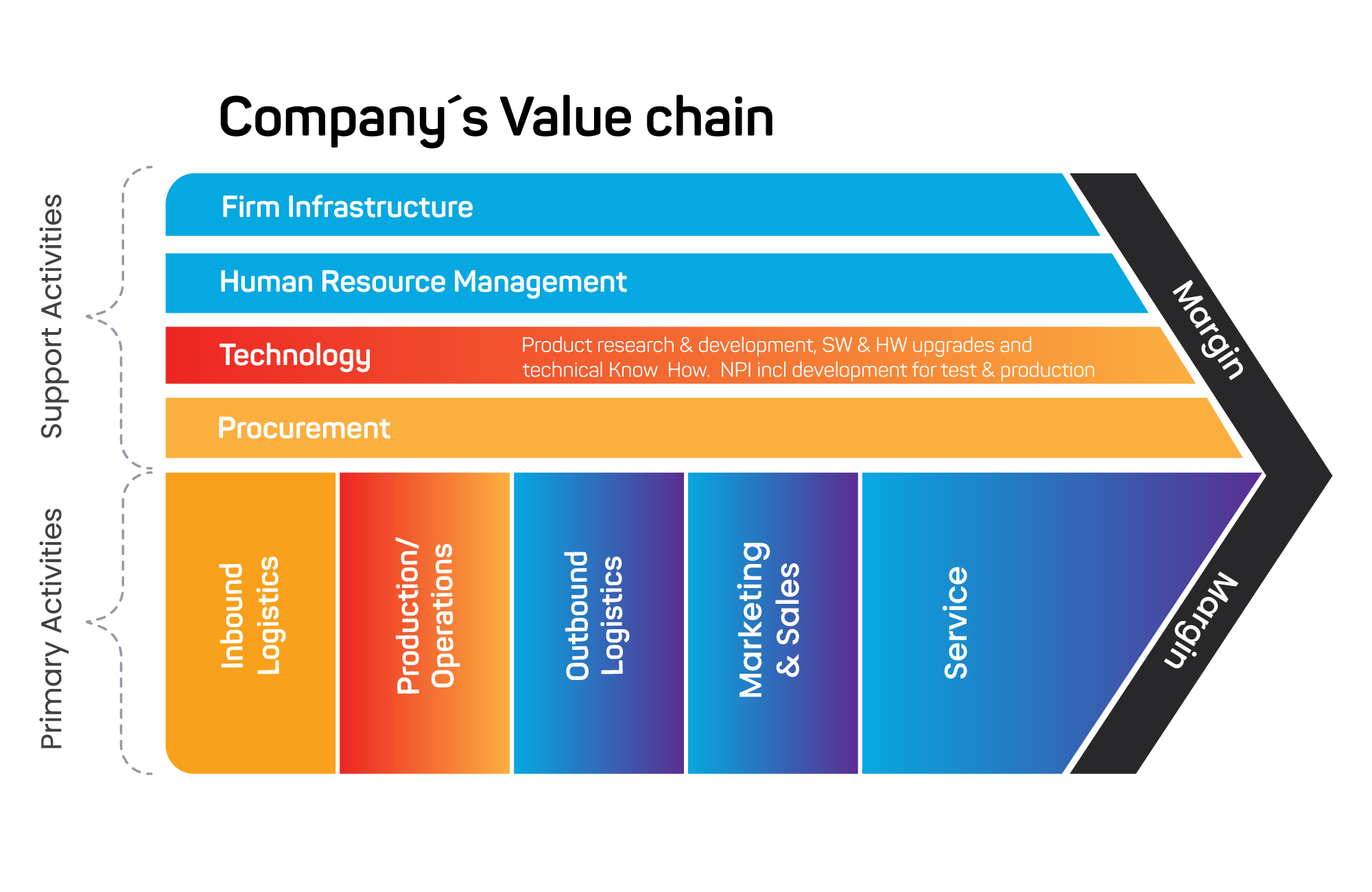

It’s the whole process from the moment there is demand for a new product – or an idea for a new product – right up until it’s in full production. It’s a major part of the New Production Introduction (NPI) process in a company’s value chain and if you want to know where it fits in terms of primary and support activities within a value chain, check out this diagram that illustrates it perfectly.

As you can see it sits firmly in production and operations, but also falls under inbound logistics as managing the supply of the goods and services you need to make your product is a crucial part of industrialization. We’ll be covering the individual steps of industrialization when we talk about the Industrialization Circle in our next blog, but for your reference the steps are Plan, Analyze, Specify, Develop, Ready Production, and Produce.

How about we give a real-world example of when industrialization was needed but not heeded?

The DMC Delorean

It could well be the most recognizable car in history. Apart from the Model T and perhaps James Bond’s Astons, there definitely aren’t other vehicles that have had as much attention as this one and its trademark gull-wing doors have stood the test of time in terms of style. But what does it have to do with industrialization?

Well, the DeLorean was an unmitigated disaster. On the surface that’s quite odd because it’s got a widely loved style, it didn’t have any major technical faults (apart from lights draining the battery) so what was the problem?

Well, in case you’re not familiar with the storied history of its production, let us fill you in. The DeLorean was actually manufactured in Northern Ireland and if your immediate reaction to that is “I’ve never heard of Northern Ireland producing cars” you’re not the only one. NI certainly doesn’t have the auto manufacturing pedigree of Germany or the US and because of that, the DeLorean’s product was doomed from the start.

That’s because setting up a large-scale manufacturing site in a place that doesn’t already have the infrastructure, talent, or experience to make it a success is a recipe for disaster. If DMC had gone through the industrialization process, it could have been saved from its fate.

DMC Delorean, manufactured in Northern Ireland.

Also, many of the various concepts of that car had different engine configurations throughout its development. That’s not necessarily a bad thing, but if DMC had been privy to the NPI funnel those ideas would have been left by the wayside early on and less money and time would have been wasted during prototyping.

In the NPI funnel, if ten ideas enter it, only 1 makes it out. If, during your research, you see it’s too hard to produce, too expensive, too late to market, whatever it is, it doesn’t make it to volume. If the work at the top of the funnel isn’t done properly, then a product can make it into Volume Production and flop – just like with the DeLorean.

We often like to daydream about what could have been with products we were excited about that didn’t quite make it, or releases that years later look like they had potential that was missed because industrialization wasn’t carried out. Don’t even get us started on Blackberry.

What we do know though is that companies that do industrialization the right way are the ones that survive. Electronics manufacturing throws more than enough external pressures at you that you don’t also want to be worrying you’ve not done your own work properly.

Stay tuned for our next article, where we’ll go another level deeper to investigate the individual steps of industrialization and where companies often trip up.

Don´t miss these articles:

The Definition of Industrialization In 2024

When you think about industrialization, what comes to mind? If you Google it you’ll.. read more

How We See The Industrialization Circle

This time we’re going one level deeper, looking at the individual steps of industrialization… read more.

In Industrialization, Planning Is Everything

Plan and Analyze. If you don’t get these two steps right, your industrialization will fail…. read more.

Looking for a partner to guide you through effective industrialization?

We’ve got the experience and expertise to get you where you want to go.