Well, well, well, we’ve made it to the final steps of industrialization and the final piece in this five-strong series of blogs on the topic. If this is your first time diving into the series, we recommend you head back to the start to catch up (it’s honestly worth it). If, however, you’re reading this we’ll assume you’re up to speed and get right into Ready Production and Continuously Improve.

Ready Production?

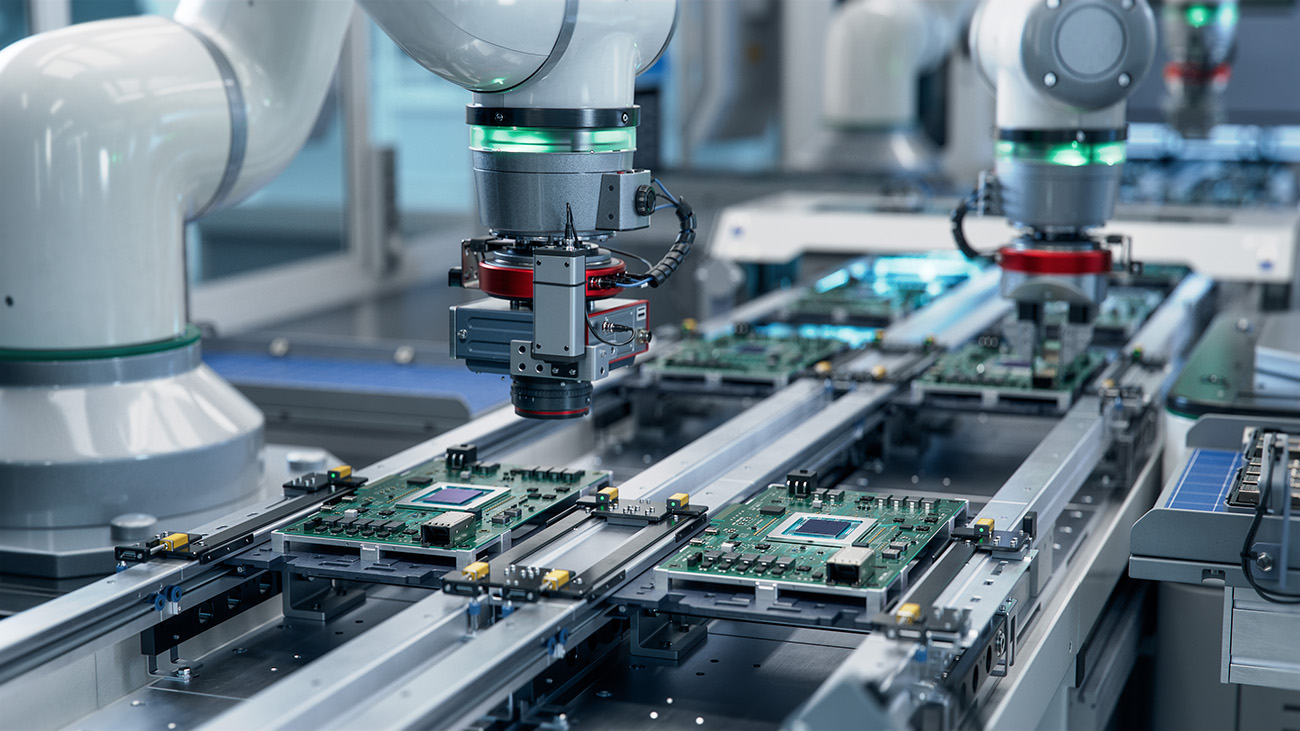

Ready Production is where all your hard work planning and preparing through the rest of the industrialization circle really starts to bear fruit. It starts with bringing a well-structured production plan to life and beginning both the First Article Inspection (FAI) and Factory Acceptance Testing (FAT) process, which are critical in evaluating – if everything you have done up to this point has worked.

Don’t worry if there are issues though. The point of these tests is to understand everything that isn’t working before you turn everything up to eleven. Consider running small initial batches to refine processes, using Process Failure Mode Effect Analysis (PFMEA) to mitigate risks throughout production.

Once those tests are passed, you can carefully press the big green button and begin rolling units off the production line. It’s a really exciting moment that anyone outside of manufacturing doesn’t really ‘get’. There’s a deep satisfaction felt when all your hard work finally meets at a physical product that is ready to be shipped to customers.

But this is just the start of a much longer journey – one of continuous improvement.

Getting Better And Better

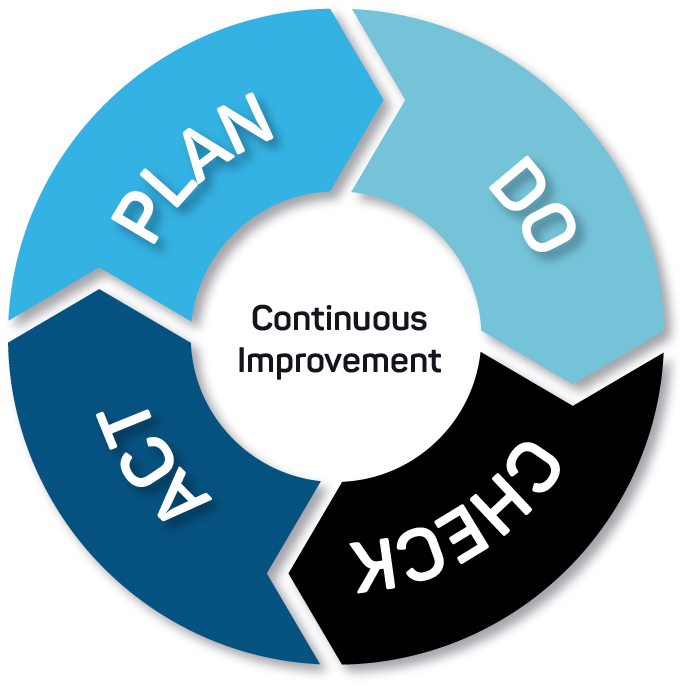

We’re not going to bore you by talking about continuous improvement in the ways you’re used to. As a product owner working in 2024, you’ll already be familiar with the concept of continuous improvement. What we will do, however, is shed some light on why continuous improvement fits so neatly into our view of industrialization, and how the work you’ve already done can immediately turbocharge this phase.

It’s important to think about continuous improvement as a holistic approach. You can’t continuously improve just one function of production endlessly. Not just because there are diminishing returns at each point of improvement, but because all the steps of production that relate to that one will ultimately anchor how far it can go. You can optimize your machinery to a point of perfection, but without a supply chain that’s geared up to supply you with the quantity and quality of parts you need, it won’t matter.

But don’t let that thought bring you crashing back down to Earth after the heady heights of getting production live. If you’ve done the hard work and really focussed on industrialization, committing to each step of the circle, then you’re already going to be well ahead of your competition. And, looking at it in an optimistic light, there’s a whole heap of things that you can make better over time.

Putting in place monitoring tools like WATS – as we suggested back in the Develop phase – facilitates real-time data analysis and proactive decision-making, crucial for addressing production issues at the same pace the market expects you to. We might well be biased about how helpful the WATS solution can be, but seeing as we’ve been helping manufacturers with industrialization for a quarter of a century, we really do know what we’re talking about. Access to test data, across your production, without all the manual work involved in collating and analyzing it yourself is a game changer. If you want to continuously improve, it really is the best place to start.

Thank you for following this series on industrialization. At Virinco, we are dedicated to helping manufacturers like you achieve and surpass your production goals. So to find out how we can support you, get in touch today – we’d love to chat.

Did you miss any of the other articles?

Here are all the articles in the industrialization series:

The Definition of Industrialization In 2024

When you think about industrialization, what comes to mind? If you Google it you’ll.. read more

How We See The Industrialization Circle

This time we’re going one level deeper, looking at the individual steps of industrialization… read more.

In Industrialization, Planning Is Everything

Plan and Analyze. If you don’t get these two steps right, your industrialization will fail…. read more.

Developing Production And Testing – One Key To Successful Industrialization

This stage is pivotal, making sure your brilliant ideas and detailed designs translate into a viable, market-ready product… read more

Ready Production And Continuously Improve

The final steps of industrialization – Ready Production and Continuous Improvement – are where the magic happens… read more.