Many production challenges start long before products reach the factory floor. When products are not designed with testing in mind, production verification becomes slower, more complex, and harder to scale. Designing for Testability (DfT) helps teams reduce risk and achieve stable, high-volume production.

Testability starts with product architecture

Production testing verifies that each unit meets functional and performance requirements before shipment. However, how efficiently this can be done depends heavily on product architecture.

Limited access to signals, complex mechanical assemblies, and missing diagnostic interfaces all increase test complexity. As a result, production teams often compensate with manual steps and longer test sequences, which reduces throughput and increases variation.

Addressing testability during product design avoids many of these downstream challenges.

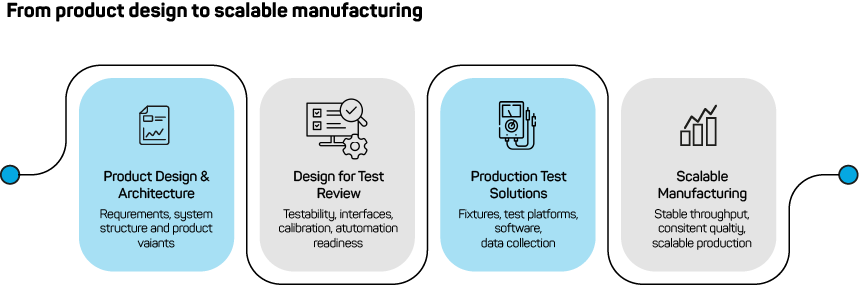

Design for Test as the link between design and production

Design for Testability (DfT) acts as the bridge between product development and scalable manufacturing.

Product Design → DfT Review → Production Test Solutions → Scalable Manufacturing

By introducing a structured DfT review early in the design phase, teams can align product architecture with verification and calibration requirements before production begins. This includes hardware, software, and mechanical aspects of the product.

Typical DfT considerations include:

- Access to signals and communication interfaces

- Support for automated diagnostics and calibration

- Mechanical accessibility for fixturing and probing

Designing for Test enables stable production ramp-up

When products are designed with testability in mind, production teams can implement more automated and repeatable verification.

This reduces operator dependency, shortens test time, and supports consistent quality across shifts and locations. As production volumes increase, standardized test approaches become essential to maintain stable throughput and predictable quality.

Small design decisions made early can therefore have a major impact on production efficiency later.

Test strategy is part of product strategy

Production test should not be treated as a downstream activity. Instead, verification requirements should influence product architecture from the earliest design phases.

Close collaboration between R&D, test engineering, and manufacturing reduces redesign cycles, shortens ramp-up time, and improves long-term production stability.

From design decisions to production performance

Designing for Test does not require major redesigns. Often, small adjustments made early can eliminate significant complexity later.

By treating testability as a design parameter alongside cost, performance, and reliability, companies can build products that scale efficiently into production and maintain stable quality over time.

How Virinco Helps R&D Teams Prevent Product Recalls and Improve Design

Why Custom Test Platforms Are Key to Reliable Electronics

In electronics manufacturing, testing is not optional – it’s essential. Read more

In Industrialization, Planning Is Everything

Plan and Analyze. If you don’t get these two steps right, your industrialization will fail…. read more.