In our last article, we gave you a top-level tour of industrialization, what it is, what happens if it’s missed, and why we’re best placed to cover the topic. This time we’re going one level deeper, looking at the individual steps of industrialization, how they feed into one another, and where companies sometimes misjudge the work required to do it right.

Ready?

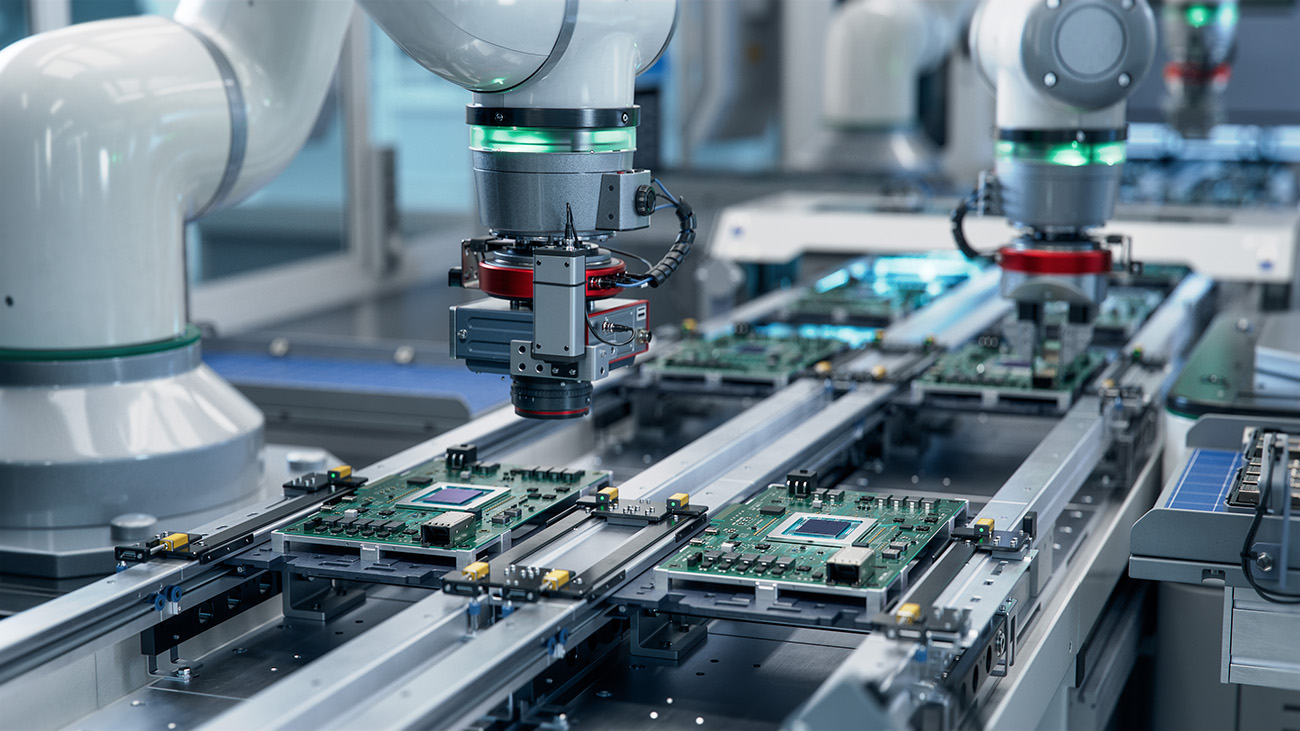

What Is The Industrialization Circle?

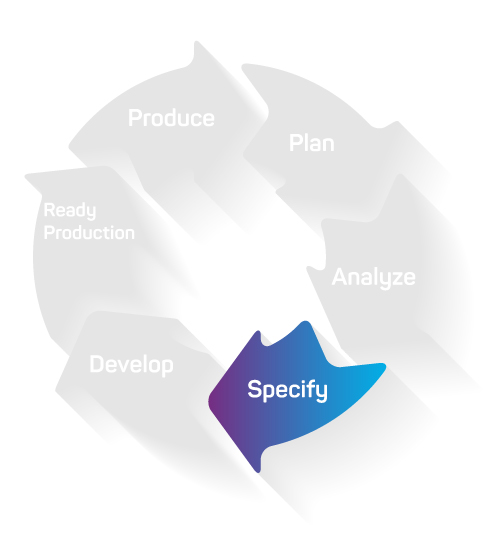

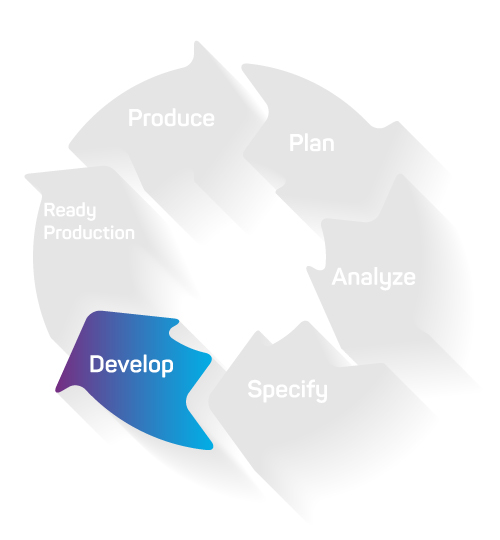

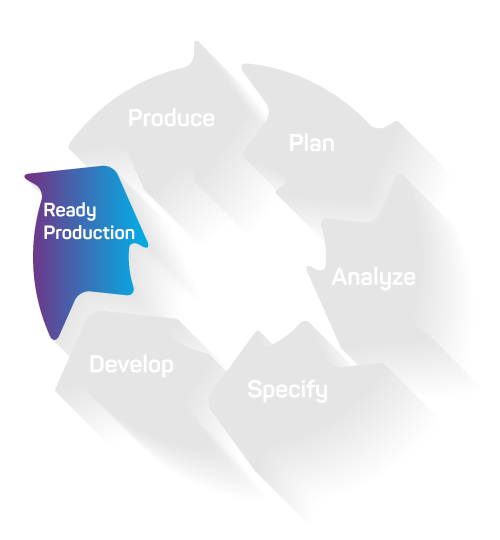

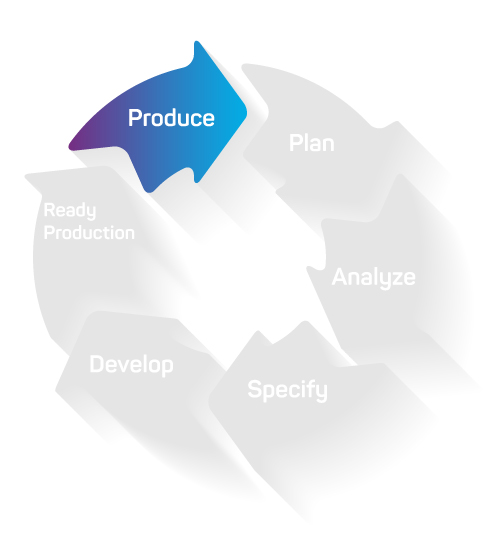

Simply put, it’s the clear layout of the broad steps of industrialization and how they feed into one another. The six steps of industrialization are Plan, Analyze, Specify, Develop, Ready Production, and Produce.

We can do better than that though, here’s a diagram that shows it off in all its glory.

The circle shape should give you some idea that this is a continuous process that forever feeds into itself – or at least it should (more on that shortly). The first steps are often the hardest but also the most important, and that is absolutely the case here. We really can’t stress that enough, so we’re making the next article in this series all about Planning and Analyze and how they set the tone for everything that comes after it.

At the other end of the circle, we often work with partners who get to Produce and then forget to carry on with industrialization. That’s a big shame because the information they get during production – and once a product is live in the market – is critical in improving not just that product, but also subsequent products – whether they are variations or even entirely new lines. Even if you have a wide variety of products, what you learn during industrialization can be applied to the way you work with suppliers, can help you set up testing regimes, and even help organize contract manufacturers: all the things that long-term success hinges on.

Every Step Of Industrialization Broken Down

To understand what each of the steps entails here is a quick reference guide. As an interesting exercise, as you read through the steps, try and think about what your company does in this sequence and if there’s anything you do particularly well or something that’s maybe missing. If there is something lacking, we’re always here to help.

Plan

Planning is all about looking at the picture. Before you start to develop a new product, consider: what are your business goals in the short, medium, and long term? How can this product contribute or potentially detract from achieving those goals? This is going to differ from business to business, so a contract manufacturer that produces thousands of items is likely going to feel less impact from a new product than a consumer electronics brand realizing a new line of products. But, as always, this is where you figure all that out.

Analyze

This is where you get into the weeds of the product idea itself. Is this something your company has seen a gap for, or has there been significant customer feedback to suggest there’s broader demand for it? Market research, IP research, risk analysis, the more work you can do here to understand a product and its potential in the market and as something you produce, the better its chances are.

Specify

Once you know that your product has a chance to not just survive the market, but actually be a success, it’s time to look at the technical scope of what it is you want to produce. This is going to involve workshopping with the teams responsible, defining product requirements, testing requirements, and project resource planning. If you can’t confirm any of those aspects, more work is going to be needed to get the components, test solutions, or resources you need.

Develop

If you’re at this point, you’re now heavily invested in this product and are at the point of pivoting from ideas and definitions to engineering. Now is the time when you design, run sims, begin to prototype, build the test solutions back from Specify, and set up the compliance and QA (Quality Assurance) processes. It’s also worth noting that you need to look at your supply chain, is there redundancy in the event a key supplier goes offline? This is very important because you could set up the best production environment in the world, but without the right parts, and enough of them, it won’t matter.

Ready Production

Even though you’ve now defined pretty much everything, you now need to make sure you can control the variables. You also need to sign off the product with the First Article Inspection (FAI) and Factory Acceptance Test (FAT). Because you’re not producing at scale yet, finding production issues now can save you a huge amount of time and money down the line. This is often best done by only running small batches to get started, giving you a realistic test without over-committing resources.

Produce

The time is finally here, it’s time to hit the big green button so that products can begin rolling off the production line. Just because everything is in full swing doesn’t mean you can take your foot off the gas. You need to work to now continuously improve by supervising production and testing. With the data and insight you get back from production, you can start to Plan all over again, getting another product online or simply refining this one.

What If My Business Is Missing Something?

This series of articles should serve as a good introduction to the topic of industrialization, but at a point, you’re going to need the help of an expert. This is our opportunity to suggest that if you’ve found this informative so far, it really is just a taste of the knowledge of industrialization and experience working with electronics companies that we have.

If you think your business is falling down on a particular part of industrialization, or you aren’t considering it at all, get in touch with us. We’re always up for a chat, and at the very least we can hopefully put your mind at rest by showing you that it is a process you can get on top of – if you work with the right people.

For now, look out for the next blog in the series, taking an even deeper look into the Planning and Analysis steps and why that’s where so many businesses miss the mark.

Want to work with industrialization pros who understand the challenges of taking new electronics products to market? Look no further than Virinco. Contact us today.

This article is the second of a five-piece series on industrialization. Don´t miss the others:

The Definition of Industrialization In 2024

When you think about industrialization, what comes to mind? If you Google it you’ll.. read more

How We See The Industrialization Circle

This time we’re going one level deeper, looking at the individual steps of industrialization… read more.

In Industrialization, Planning Is Everything

Plan and Analyze. If you don’t get these two steps right, your industrialization will fail…. read more.

Developing Production And Testing – One Key To Successful Industrialization

This stage is pivotal, making sure your brilliant ideas and detailed designs translate into a viable, market-ready product… read more

Ready Production And Continuously Improve

The final steps of industrialization – Ready Production and Continuous Improvement – are where the magic happens… read more.