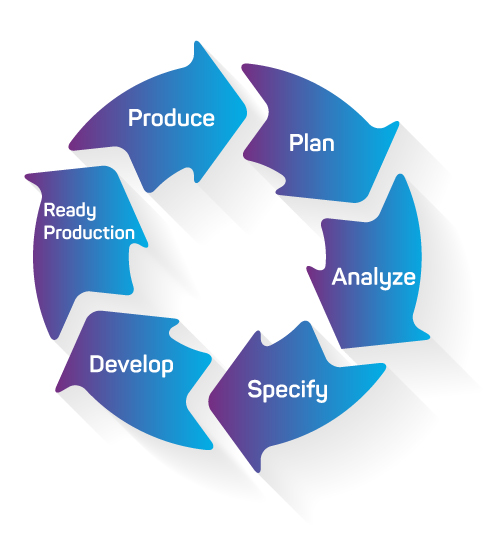

A structured industrialization process is becoming essential in modern electronics development. This article explains how the Industrialization Circle reduces risk, strengthens engineering decisions and creates a predictable path from idea to production — especially relevant when planning a new year of product development.

The Industrialization Circle has been highlighted before — and for good reason. Throughout the year, a wide range of customer collaborations, from early product concepts to advanced engineering tasks and complete test strategies, has demonstrated how crucial a structured industrialization approach truly is. New products, rapid prototyping cycles and several production transfers have all revealed the same pattern: teams that follow a clear, predictable framework move faster, reduce risk and achieve stronger long-term performance.

As a new year begins, many organizations revisit their roadmaps, refresh their development plans and prepare for new investments. This makes it the ideal moment to take a renewed look at The Industrialization Circle in electronics development. The cycle provides a proven, systematic way to guide a product from idea to stable production, while maintaining quality, traceability and manufacturability.

Product development continues to grow more demanding. Electronics are more complex, compliance expectations evolve quickly and customers expect stable performance from day one. Without a robust industrialization strategy, even strong ideas can struggle to become profitable and sustainable products.

This is where the Industrialization Circle becomes essential.

1. Plan

Every successful product begins with structured planning.

This phase sets the overall direction, aligns expectations and creates a realistic foundation for the entire lifecycle.

Typical activities include:

• defining requirements and constraints

• identifying early cost drivers

• mapping compliance and safety needs

• outlining timelines and milestones

• establishing test considerations early

A strong plan reduces uncertainty and prevents costly rework later, especially when combined with early involvement from experienced engineering and end-to-end product development services.

2. Analyze

Before committing resources, each concept must be evaluated thoroughly.

This phase provides clarity and ensures that early decisions support long-term stability.

Typical focus areas include:

• technical feasibility

• risk identification

• architecture considerations

• manufacturability and testability

• expected performance versus requirements

Thorough analysis leads to smarter choices and a more predictable development path.

3. Specify

A solid specification acts as a bridge between design, engineering and production.

It translates high-level ideas into clear, structured requirements.

This phase often covers:

• system design definitions

• interface descriptions

• documentation standards

• test criteria and acceptance limits

• environmental and regulatory requirements

Clear specifications minimize misunderstandings and reduce the risk of later redesigns.

4. Develop

With a solid foundation, development can progress efficiently.

This is where the product takes shape through multidisciplinary engineering.

Key activities typically include:

• mechanical design

• electronics design and layout

• embedded software development

• prototype builds and functional verification

• test-system development aligned with product maturity

Close collaboration across disciplines ensures that all components evolve in a balanced, integrated way.

During this phase, engineering teams often work closely with dedicated test developers to ensure the product and testing mature together. Explore more about advanced test development here:

Custom Test Platforms.

Custom Test Fixtures.

5. Ready Production

Before scaling, the entire chain must be verified.

This phase transforms the prototype into a fully production-ready solution.

It often involves:

• pilot builds

• refinement of assembly processes

• test integration and validation

• documentation and work instructions

• supply-chain verification

• environmental and endurance testing

A strong pre-production phase reduces risk during ramp-up and ensures consistent quality from day one.

6. Produce

The final stage brings the product into stable manufacturing.

Here, quality, test robustness and lifecycle management become critical.

Important elements include:

• continuous improvement

• traceability and monitoring

• firmware updates and version control

• component lifecycle handling

• corrective actions and feedback loops

Production is not an endpoint — it is part of an ongoing process that ensures the product remains reliable, compliant and maintainable throughout its entire lifecycle.

Starting the Year With a Stronger Product Strategy

As many companies set new goals for the coming year, the Industrialization Circle provides a powerful framework for smarter planning and more predictable execution. It connects engineering, testing and manufacturing into one cohesive process, helping organizations launch dependable products while reducing risk and cost.

A structured approach is not just beneficial — it is becoming a necessity.

For teams working with electronics development, advanced testing or production scaling, the Industrialization Circle remains one of the strongest roadmaps available.